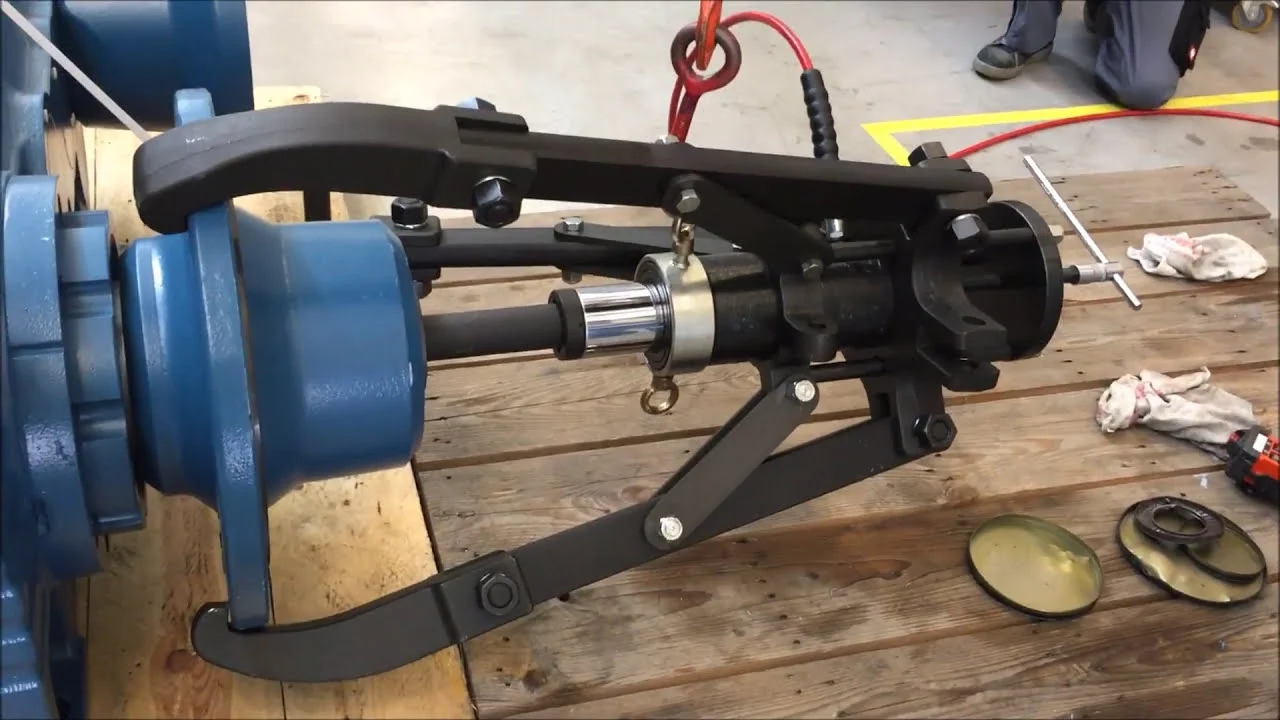

The hydraulic bearing puller uses the hydraulic starting rod to move forward directly, so the push rod itself does not rotate. The hook seat can directly adjust the distance forward and backward along with the thread. During operation, as long as the handle swings forward and backward slightly, the hydraulic starting rod moves forward and retreats accordingly, the corresponding object can be pulled out.

Bearing Removal With A Bearing Puller

When using a bearing puller to remove the bearing, the price is particularly cheaper, but its disadvantage is that it may scratch the shaft if carefully operated. Because of the difference in mechanical mechanism and driven power, pullers can be divided into hydraulic pullers and mechanical pullers, two-jaw pullers, and three-jaw pullers. Before disassembling the bearing, choose a suitable type of puller from the puller manufacturer with sufficient capacity to finish the task.

How to use hydraulic bearing puller?

Hydraulic gear pullers are divided into small and heavy-duty. For information on how to use small hydraulic gear pullers, please read the following article.

In this article, PullerTop mainly introduces heavy-duty hydraulic gear pullers, Puller Capacity is between 50t-300t.

Using a heavy-duty hydraulic gear puller typically involves several steps:

Preparation: Make sure the puller is in good working order and that all necessary safety precautions are in place. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses.

Positioning: Move the gear puller to the location where the gear needs to be removed. Wheels on the bottom of the puller make it easy to move and position.

Attach: Securely attach the puller arm or jaw to the gear to be removed. Make sure the attachment points are secure and properly aligned with the gears.

Hydraulic settings: Connect the hydraulic pump on the hydraulic bearing puller to power and set the pressure gauge.

Apply pressure: Activate the hydraulic system to apply pressure to the puller. This will create a force that gradually pulls the gear away from the shaft or mount.

Monitoring: Pay close attention to the towing process to ensure that the towing process is smooth and safe. Check for any signs of resistance or adhesion that might indicate a problem.

Extraction: Once the gear has been pulled sufficiently out of its position, stop hydraulic pressure and carefully remove the gear from the shaft or mount. Please be careful to avoid any sudden movements that may cause injury or damage.

Safety: After completing the gear removal task. Store the gear puller in a safe location until needed again.

Product instructions and guidelines given by the manufacturer must be followed when using a hydraulic bearing puller to ensure safe and effective operation. In addition, proper training and experience are also important for the operator.