How do you bleed air out of a hydraulic hand pump?

You bought a new hand pump but found that the hand pump does not suction oil when it is working. Even if you press the handle of the hand pump repeatedly, the hand pump starts to suction oil, and the oil intake is much less than normal. Please don’t worry, this is because there is a shortage of oil inside the fuel tank of the hand pump and it has not been used for a long time, and air has entered the inside of the plunger of the hand pump. At this time, we need to bleed the air inside the plunger, and the manual hydraulic pump can work normally.

- Fill the manual pump tank with hydraulic oil and connect the manual pump, hydraulic hose and hydraulic cylinder.

- Turn the air release valve counterclockwise to open the air release valve.

- Tighten the oil return valve of the manual pump and press the handle repeatedly to discharge the air in the piston. After the air is discharged, turn the plunger bleed screw counterclockwise and wipe the surface of the hand pump with a rag. Tighten the plunger bleed screw and loosen it during normal operation.

How to solve the problem when the Hand pump does not discharge oil?

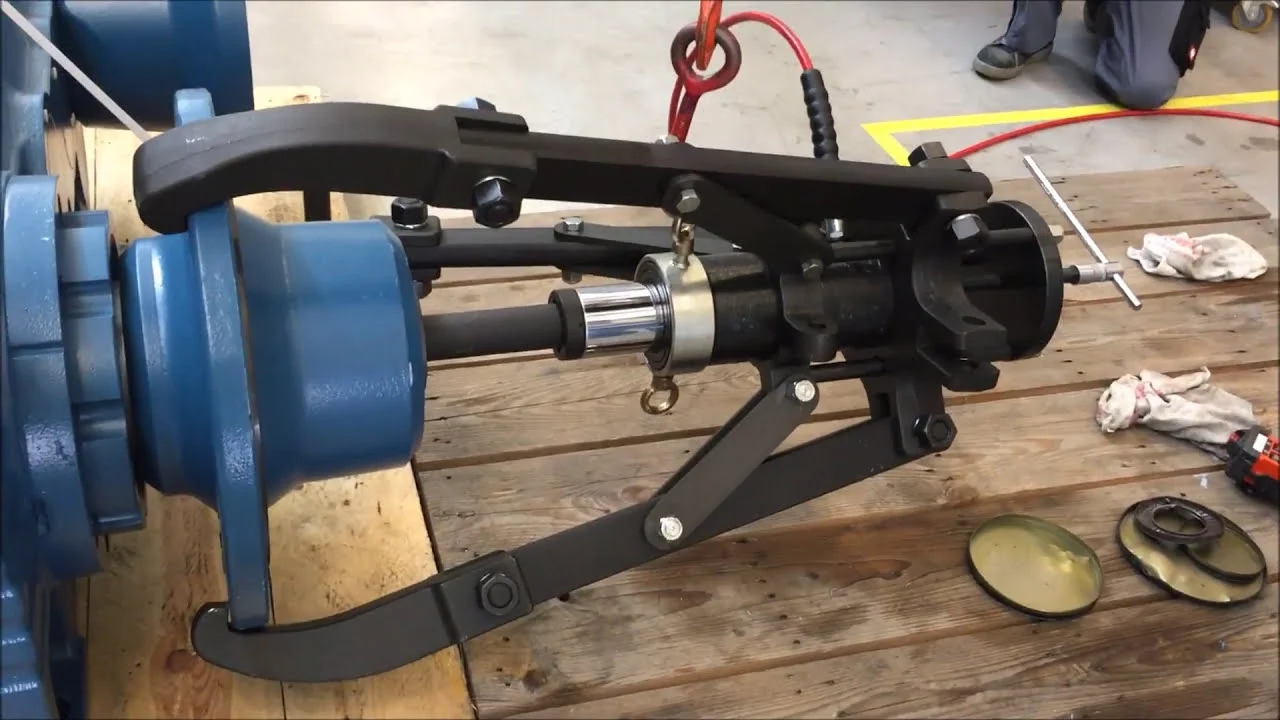

Let’s take a Pullertop P-80 two-speed hydraulic hand pump as an example,in order to better solve this problem, please follow these steps:

- Loosen the hexagonal socket screw on one side and take out the spring and steel ball inside.

- Take a magnetic Allen wrench and carefully and repeatedly insert it into the one-way valve hole to suck out any garbage that may be inside.

- Then, put in the steel ball, spring and tighten the hexagon socket screws, and then repeat this step on the other side

- Finally, follow the step of removing air again to ensure that the manual pump can work normally.